Busy bees – a behind the scenes look at developing Synergy’s true-to-nature honey range

In our last blog post, we discovered how honey is gaining traction across the food and beverage industry and is increasingly used to flavour a wide range of applications.

In light of this recent trend, we have been working in close partnership with a beekeeping society to develop our brand new honey flavour range. Here, I’ll explain how we captured the unique characteristics of honey samples collected from an apiary, alongside those from a market leading runny honey, set honey and Mānuka honey, to develop five distinct flavour profiles.

Extracting the essence of honey

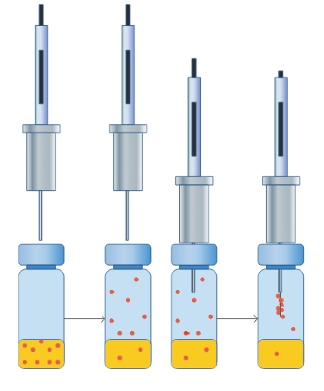

The first stage of flavour analysis involved evaluating the samples’ aroma, by capturing and measuring the levels of aroma compounds released into the air by the honey. To do this, our scientists used a method called Solid Phase Microextraction (SPME) – a technique which is widely used across the industry to enable the extraction of aromatics. A needle is coated in a polymer and inserted into the sample. The polymer acts as a sponge, soaking up the aroma compounds emitted by the samples:

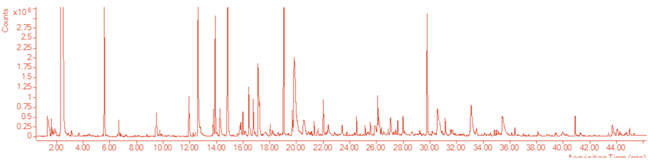

These flavour compounds are released into a gas chromatograph, a machine which separates them by using a gas to carry them through a long thin coil, called the column. Depending on how volatile the aroma chemicals are, they travel at different speeds through the column. In general, the more volatile the chemical, the quicker it will reach the end, with each peak representing a different chemical. The result of this analysis is a chromatogram, which plots time versus intensity for each chemical peak:

As each chemical leaves the column, it enters the mass spectrometer. The mass spectrometer causes the molecules to break apart into molecular fragments. From the fragmentation pattern of an unknown peak, flavour scientists are able to identify the chemical responsible.

Sweet discoveries

By comparing the chromatograms and fragmentation patterns for each of the honey samples, Synergy’s scientists were able to identify the similarities and differences between the range of profiles. Here are some of their key discoveries:

- Phenyl ethyl alcohol and phenyl acetaldehyde were found in every honey sample. Both chemicals have a very typical floral odour, frequently associated with honey. Surprisingly, though, the rapeseed honey contained very low levels, indicating the floral notes were coming from other sources.

- Linalool oxide was found at higher levels in the rapeseed honey, identifying it as the source of the floral notes.

- The dark Mānuka honey sample also contained high levels of the chemical components naturally produced during the caramelisation process. These were later used to impart soft caramel-like nuances in the Mānuka flavour profile.

- The Mānuka honey sample contained organic esters, naturally produced by many species of plant, which provided a source for the distinct herbaceous/medicinal notes commonly associated with this particular profile.

These findings were then used to develop a range containing five distinct honey profiles, including:

- Comb

- Mild

- Dark

- Mānuka

- Floral

Superior sweetness

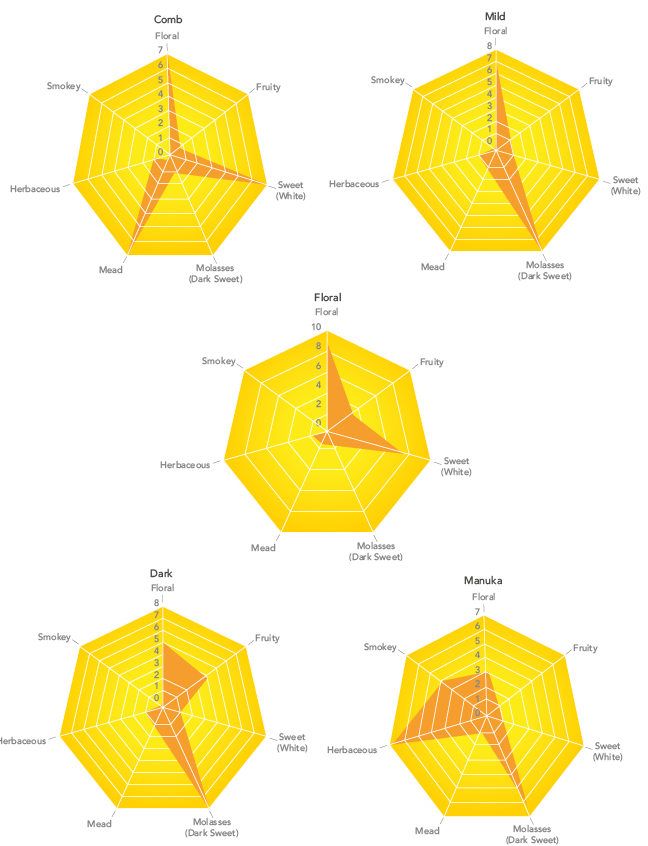

Once confident with the five new flavours, it was time to put them to the test and ensure they could deliver the expected flavour impact across different applications. Sensory evaluation was used to measure the flavour profiles of each individual flavour. Here, an expert flavour panel was asked to score a range of samples based on seven key descriptors common to honey:

- Floral

- Fruity

- Sweet (white)

- Molasses (dark sweet)

- Mead

- Herbaceous

- Smokey

The results are illustrated in the following flavour maps:

In addition, the flavours were tested across wide variety of applications and are suitable for the following:

- Alcoholic beverages

- Beverages

- Sports nutrition

- Dairy (including chilled desserts)

- Bakery

- Savoury

Ensuring sweet success

With extensive technical knowledge, application know-how and market insight, working with a flavour expert like Synergy Flavours is essential in creating products with real flavour impact. Our in-house flavourists not only understand sensory properties, but also how they can influence positive and negative flavour characteristics in different applications – helping you to develop winning products every time!

Contact us for details or samples on our honey range.

insights